America boasts some of the greatest steel structures and engineering in the world. Here are the 5 most popular American steel structures.

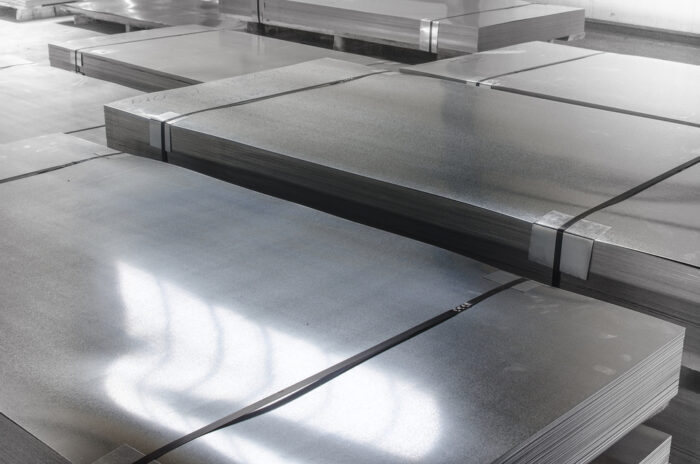

All steel is not created equal. There are several different types of steel, including carbon...

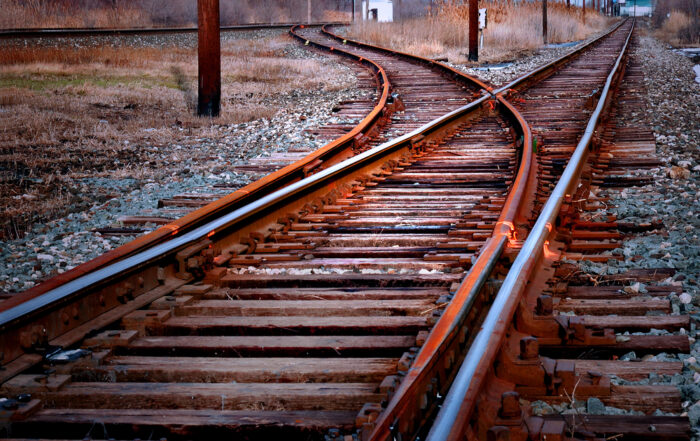

The fact that railway tracks can be reused in a number of ways might be...

Steel is renowned for its durability, hardness, and toughness. Frequently referred to as the “strongest...

The space race is currently at its height, and steel is becoming a key player...

While the world focuses on sustainability and recycling, the truth is that barely eight percent...

Recovery is the word of the year as the steel industry comes roaring into 2021....

You don’t have to have traveled much in the U.S. to have heard names like...

Citric acid is a weak acid that occurs naturally in fruits, such as lemons and...

In the early years of baseball, the stadiums in which the games were played were...

Steel piping is commonly used due to its durable nature. It can withstand high pressure...

June is just getting started, but that hasn’t stopped heat waves from hitting large regions...