It then gives a better product and helps to keep everything clean. Of course, stainless steel also releases no chemicals and does not corrode. It lasts longer without ever tainting the product.

Steeped in Steel…

In the US, much of the steel supply comes out of Granite City, Illinois. It is distributed throughout the country for use in various industries. We primarily use steel for manufacturing. But, a portion is also used to create the tools and machines associated with the dairy industry.

Stainless steel’s functionality, versatility, and dependability make it the leading material for the hygienic integrity of our dairy products.

Why Stainless?

One may wonder why stainless steel has been appropriated for the food and dairy industries. Would aluminum not be a viable option? While aluminum does have some useful qualities, the features of stainless steel surpass those of any other available materials. The incredible features of stainless steel are as follows:

- Has bacterial and chemical neutrality to the food or dairy product.

- Can be cleaned and disinfected so as not to compromise the appearance or freshness of the food or dairy product.

- Resists corrosion resulting in durability and reliability.

These qualities, along with the ease with which stainless steel is acquired, makes this product the indisputable best choice for ensuring proper processing, transportation, and storage of food and dairy products.

Stainless Steel in the Dairy Industry

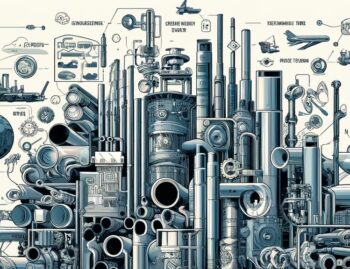

Whether used for transportation purposes or during the processing of dairy products, stainless steel tools and devices have allowed for mass distribution and storage of these products. The uses of stainless steel are varied and cover a wide range of dairy-related functions. Listed below are some mechanisms that utilize stainless steel in one way or another.

- Milk Tanks: One of the most important pieces of dairy farming equipment. A milk tank is made of stainless steel and keeps the milk cool until it can be attached to a tanker and delivered to its destination.

- Road Tankers: Road tankers transfer the product to an insulated stainless steel tank. The tank will ensure freshness and hygienic integrity until delivery.

- Vats & Churns: Vats are used for pasteurizing dairy products. Churns make cheeses, butter, and other dairy products.

- Storage & Maturation Tanks: Maturation tanks are at the core of the process of making milk, cheeses, cream, ice cream, and even yogurts. A large stainless steel vessel is well insulated and allows for a variety of tasks. Once the product has been made, it is stored in a stainless steel container until distribution.

All in all, stainless steel has proven it is the very best material to ensure the hygienic integrity of our beloved dairy products.