Comprehensive Guide to Carbon Steel Pipes: Advantages and Applications

In the vast field of construction and engineering, the choice of materials can significantly impact the outcome of a project. Carbon steel pipes, renowned for their versatility and strength, are pivotal in various industrial applications.

Explore the benefits and uses of carbon steel pipes, providing essential insights for engineers, procurement professionals, and business owners.

What Makes Carbon Steel Pipes Stand Out?

Carbon steel pipes are prized for their robust composition, primarily made from iron and varying carbon levels. This variation in carbon content directly influences their mechanical properties such as hardness and tensile strength, making them suitable for a diverse range of applications across industries like manufacturing, construction, and transportation.

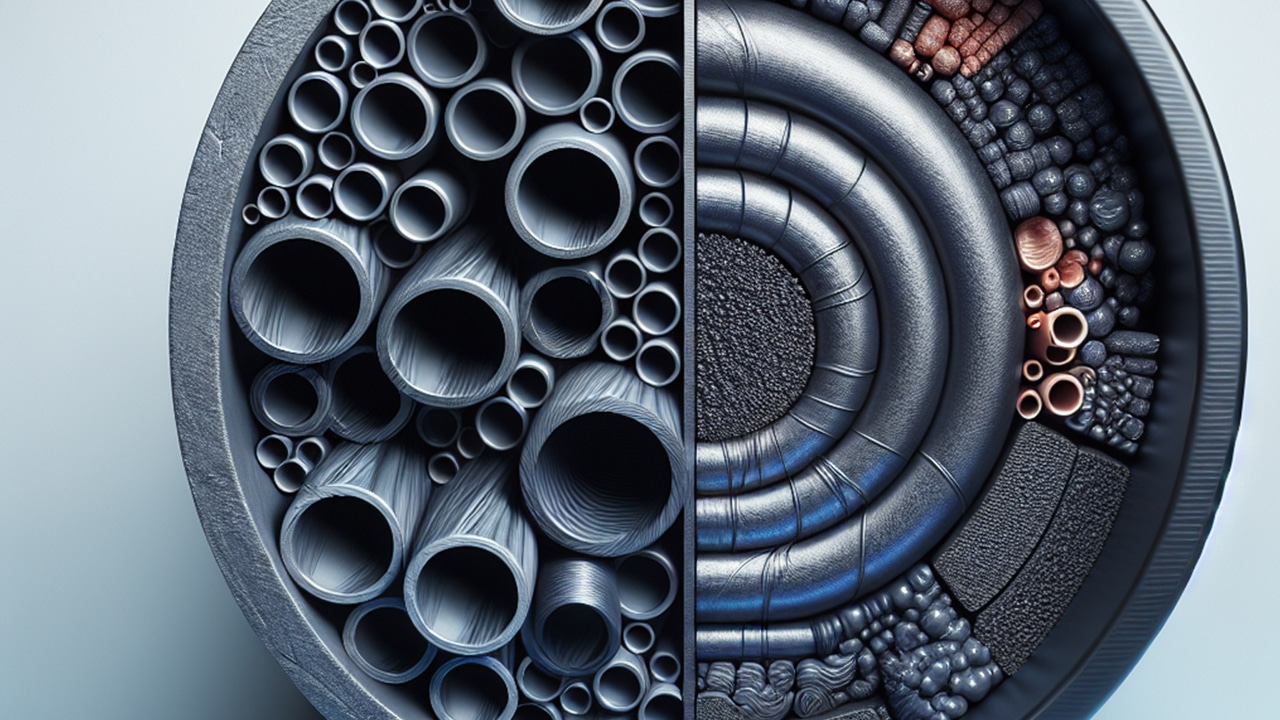

Types of Carbon Steel Pipes

Seamless Carbon Steel Pipes:

Known for their strength and uniformity, these pipes are ideal for high-pressure applications.

Welded Carbon Steel Pipes:

These are cost-effective and are predominantly used in low-pressure settings.

Advantages of Carbon Steel Pipes

Durability:

Exceptional strength enables them to withstand high pressures and harsh operational conditions.

Versatility:

Adaptable to various applications, from underground plumbing to structural components in buildings.

Cost-Effectiveness:

Offers a lower cost alternative to materials like stainless steel, without compromising on performance.

Applications in Construction and Industry

Carbon steel pipes are integral to the construction sector, used in structural frameworks, plumbing, and more due to their ability to handle pressure and vibrations.

Industrially, they transport gases and fluids in the energy sector, serve as components in automotive manufacturing, and facilitate chemical processing with their resistance to corrosive substances.

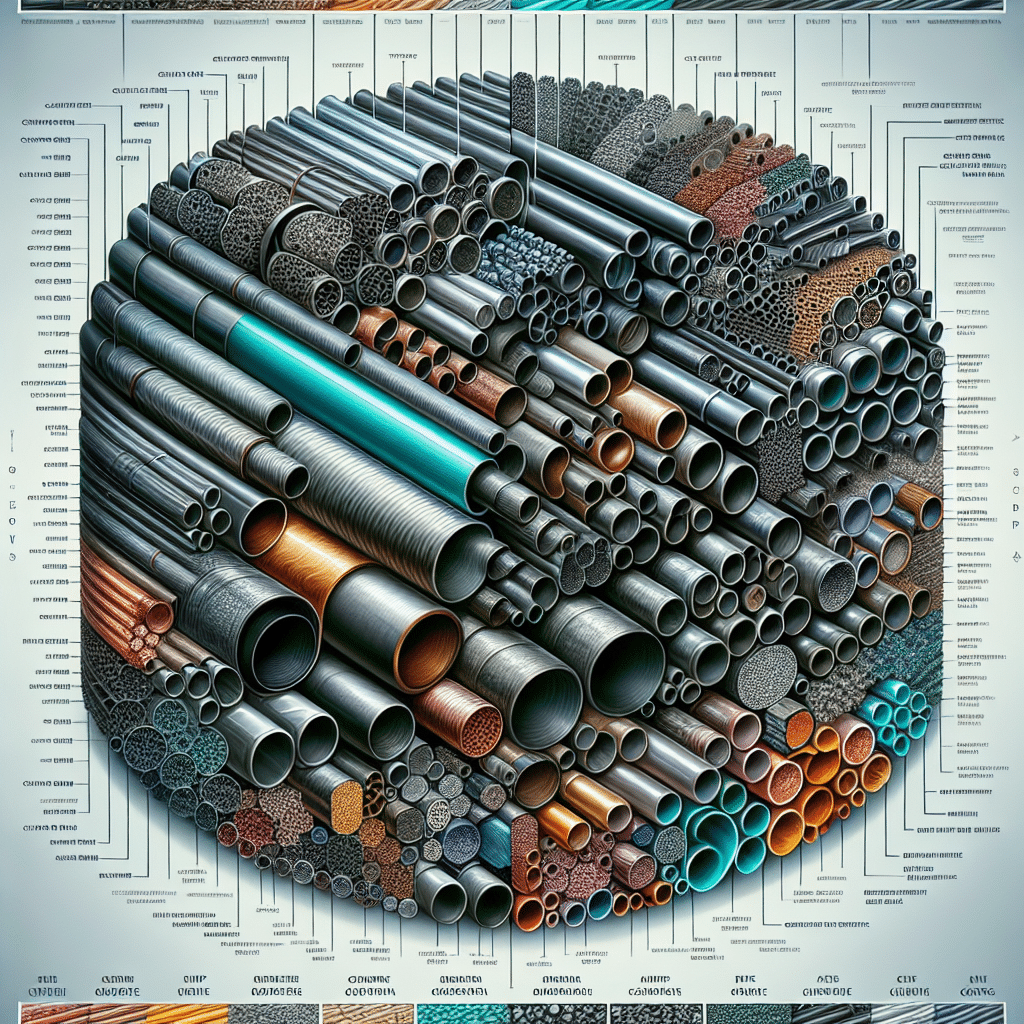

Comparing Carbon Steel Pipes with Other Materials

When compared to alternatives like PVC, stainless steel, or copper, carbon steel pipes generally offer a better balance of strength, durability, and cost-effectiveness. They outperform PVC in strength and temperature tolerance, resist corrosion more effectively than copper, and are more cost-efficient than stainless steel.

Carbon steel pipes offer several advantages over these materials. For instance, they are stronger and more durable than PVC pipes.

Compared to copper, carbon steel pipes are more resistant to corrosion. They also have a higher pressure rating.

Here's a quick comparison:

Strength:

- Carbon steel > Stainless steel > Copper > PVC

Durability:

- Carbon steel > Stainless steel > Copper > PVC

Corrosion resistance:

- Stainless steel > Carbon steel > Copper > PVC

Pressure rating:

- Carbon steel > Stainless steel > Copper > PVC

Maintenance and Lifecycle Costs

Despite their ruggedness, carbon steel pipes do require maintenance to prevent corrosion, such as regular inspections and protective coatings. However, their longevity and minimal upkeep requirements contribute to their overall cost-effectiveness.

Sustainability and Environmental Impact

Carbon steel pipes are not only durable but also have a lower environmental impact. They are fully recyclable, which contributes to resource conservation and waste reduction. The manufacturing process is also evolving to be more energy-efficient, further reducing their carbon footprint.

Standards, Specifications, and Grades

Carbon steel pipes are manufactured according to specific standards. These standards ensure quality and consistency across the industry.

The American Society for Testing and Materials (ASTM) and The American Society of Mechanical Engineers (ASME) set most of these standards. Where ASME/ASTM SA53/A53 and ASME/ASTM SA106/A106 are common standards for carbon steel pipes. In addition to standards, carbon steel pipes come in various grades. These grades indicate the pipe's properties, such as its strength and hardness.

Choosing the right grade is crucial. It ensures the pipe can withstand the pressures and temperatures of its intended application.

Future Outlook

With ongoing advancements in material science and manufacturing processes, the future of carbon steel pipes looks promising. Innovations are expected to enhance their properties and expand their applications, ensuring their role as a staple in industrial and construction projects continues to grow.

Conclusion

Choosing carbon steel pipes is a strategic decision that offers reliability, efficiency, and sustainability. As industries continue to evolve, the attributes of carbon steel pipes consistently meet the demands of complex and varied applications, solidifying their status as a preferred material choice.

Are you considering carbon steel pipes for your next project?

Contact us to discuss your requirements and discover the best options tailored to your needs.