Because countries are becoming increasingly dependent upon each other through trade, investment and financial systems, China’s slowdown could have a ripple effect across the globe. For India, that ripple could be one of expanded trade and increased steel production

Until recently, Indian steel companies could choose to produce product for internal use or for export. Today, globalization is no longer a matter of choice. The long term success of the steel industry depends on it.

Signs are beginning to arise that India might generate the next boom in the steel industry, replacing China in that role. As the Chinese steel industry has to concentrate inward to deal with the problems of excess capacity, excess pollution in the industrial areas and major cities, and low of profitability, India has an opportunity to come in and build a competitive advantage in the global arena before more efficient and larger Chinese steelmakers reenter the global market.

A plan by the Indian government called “Make in India” designed to kickstart new investments in Indian companies using fiscal measures is critical for an improvement in the country’s economy. The corporate community in India has always been cautious in its investment attitude. That trend continues. Of 192 companies polled in a Crisi survey, planned capital expansion by private companies showed that it would likely decline by 11% over 2015-16. A decline in the manufacturing sector was also forecast.

However, PM Narendra Modi’s 2014 “Make in India” plan can help change that negative attitude and boost the current steel sector slump.

The automobile manufacturing sector is one of the industries expected to benefit from the “Make in India” plan. The Indian auto industry is already one of the largest in the world. It built 23.37 million vehicles in the 2014-2015 period. This number represented a 8.68 per cent increase over the previous year. It also accounts for 7.1 per cent of India’s gross domestic product. A continuing expansion in the auto sector bodes well for a revitalized steel industry.

Due to a growing middle class, much the same as China has experienced, the demand for automobiles is increasing. And the two-wheeler industry (bicycles, motor scooters and motor cycles) is planning a rapid growth into new rural market areas of the vast country for the first time.

In recent years, India has also become a prominent auto exporter. India’s largest automobile manufacturer Tata is the world’s 17th largest motor vehicle company by volume. Within that number, they are the fourth-largest truck builder and second in bus manufacturing. When it acquired the Jaguar and Land Rover brands from Ford, Tata gave notice that it was now a world player in the auto market.

Several new initiatives implemented by the Government of India and the major automobile players working together are designed to make India the world leader in the Two-Wheeler and Four-Wheeler markets by 2020.

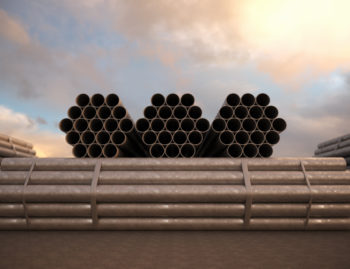

All of this planned growth has a significant positive impact on the steel industry in not only India but world-wide. While the demand for steel in China slows over the next five years, India has an opportunity to emerge as a major global steel player in its own right.

The government’s ‘Make in India’ initiative should increase the consumption of steel-base products with the potential to raise the share of manufacturing to 25% of India’s GDP. If that target is reached, it will put India on par with China and South Korea where manufacturing is a major growth driver for the economy.

An increased demand for steel products by India is a boost not only for their steel industry but for steel companies around the world. Until they can build new, more efficient steel mills, India will continue to rely on imported steel to supplement their need for the material.