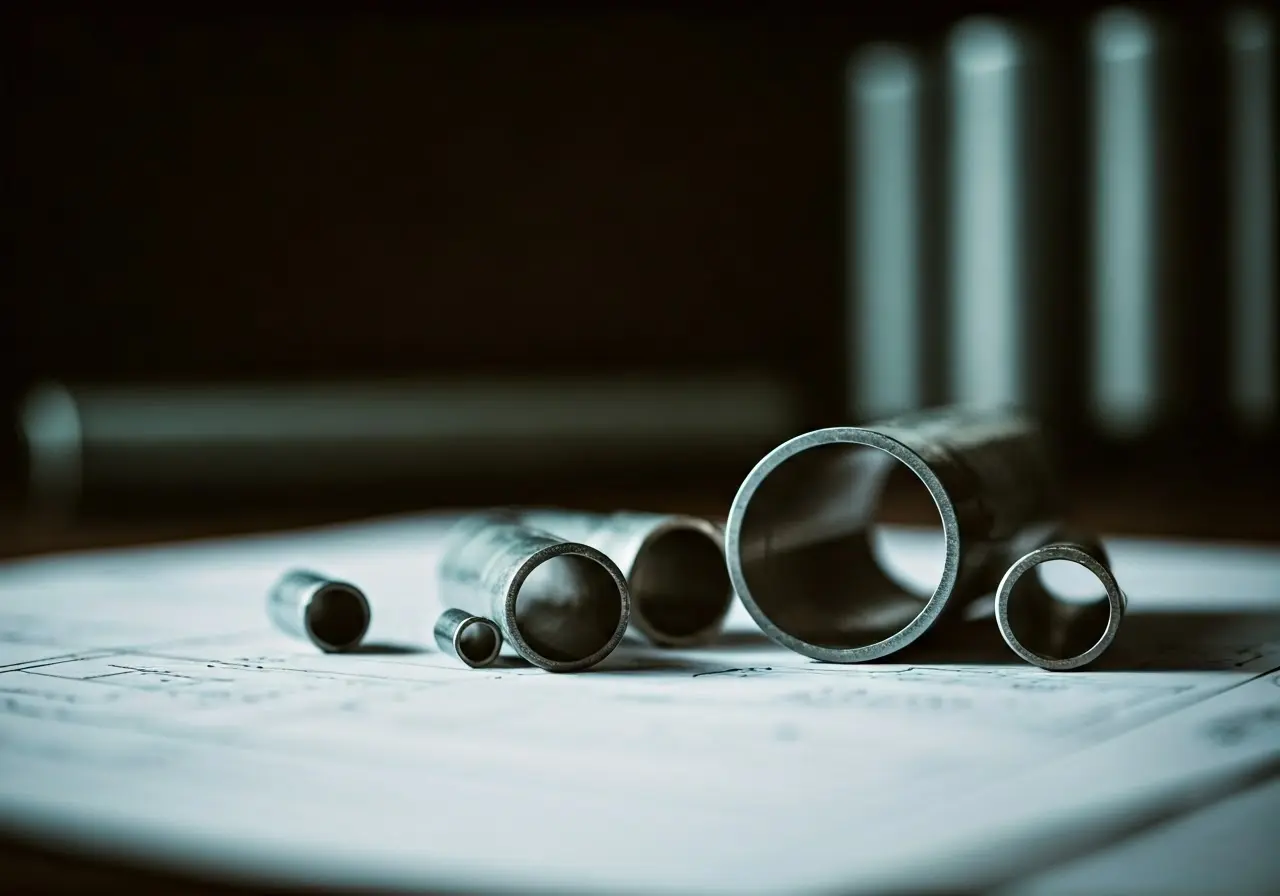

Understanding the various pipe sizes used in construction is crucial for ensuring the success and efficiency of your projects. Whether it’s a small home renovation or a massive infrastructural undertaking, choosing the correct pipe sizes can make all the difference. In this guide, we’ll walk you through the essential pipe sizes that every constructor should familiarize themselves with.

1. Small Diameter Pipes for Domestic Use

When it comes to household plumbing, small diameter pipes are a staple. These pipes are ideal for water lines leading to sinks, toilets, and showers. They typically range in size from small to medium diameters, allowing for efficient water flow without taking up too much space. Their compact size also makes them easy to maneuver around existing structures, which can be a significant advantage in renovations. Whether used for new constructions or modifications, these pipes ensure your home’s plumbing system operates smoothly and efficiently.

However, it’s not just about size; the material of these pipes also matters. For instance, copper pipes, known for their durability and heat resistance, are commonly used in residential settings. Alternatively, PEX piping offers flexibility and is easier to install due to its resistance to scale and chlorine. Whichever material you choose, ensuring the proper pipe size is critical to avoiding issues like low water pressure or leaks, potentially leading to costly repairs.

2. Medium Diameter Pipes for Versatile Applications

Medium diameter pipes serve a wide range of purposes, from residential plumbing to small commercial applications. They offer a balance between strength and flexibility, making them suitable for handling varying water pressures and other fluids. In sprinkler systems, for instance, medium-sized pipes are often used due to their ability to efficiently distribute water across different areas. Utilizing these pipes ensures that your infrastructure can support diverse applications without compromising performance.

It’s interesting to note that the choice between using PVC or ABS for these applications often depends on the specific requirements of the project. PVC piping is popular due to its chemical resistance and relatively low cost, whereas ABS is valued for its strength and sturdiness. Keeping the application in mind, selecting the right material can significantly enhance the efficacy and longevity of the piping system.

3. Large Diameter Pipes for Infrastructure Projects

Critical in large-scale infrastructure projects, large diameter pipes are designed to carry significant volumes of water and other materials. They are commonly used in urban water supply systems, sewage plants, and industrial settings. The size and strength of these pipes make them ideal for transporting major volumes without frequent maintenance. For municipal water distribution or sewage transport, such pipes are essential to ensure reliability and safety across networks.

Their robust construction is often achieved using materials like ductile iron or concrete. Ductile iron offers resilience and flexibility, making it a favored choice for water mains and sewer pipes. On the other hand, concrete piping can handle tremendous internal pressure, making it suitable for high-capacity water management systems in cities. Choosing the right large diameter pipe entails considering factors like pressure requirements and environmental conditions to avoid common pitfalls like urban flooding.

4. Heat Resistant Pipes for High Temperature Applications

These pipes are crucial in settings where high temperatures are expected, such as in heating systems or industrial processes. Made from materials that can withstand heat, they ensure the safe and efficient transport of hot liquids. Materials like stainless steel and heat-resistant alloys are often chosen for their durability and ability to maintain structural integrity under extreme temperatures. This selection ensures that industrial applications can run uninterrupted without the risk of pipe degradation or failure over time.

In industries that require precise temperature control, such as food processing or chemical manufacturing, reliable heat-resistant piping is non-negotiable. These pipes also prevent thermal expansion issues that can lead to joint and seal damage. The choice between stainless steel and newer composite materials will often depend on factors like budget constraints and environmental conditions. To minimize energy loss and ensure efficiency, thermal piping must be appropriately sized and insulated.

5. Corrosion Resistant Pipes for Chemical Handling

Handling chemicals requires special considerations, and corrosion resistant pipes are designed to safely transport corrosive materials. These pipes are essential in chemical manufacturing and storage facilities. Common materials include high-density polyethylene (HDPE) and lined carbon steel, known for their ability to resist chemical reactions that can lead to structural weaknesses or leaks. By preventing such issues, corrosion-resistant piping extends the lifespan of systems and ensures safety in volatile environments.

In environments like oil refineries or petrochemical plants, these pipes are crucial for maintaining operational safety and efficiency. Pipe materials must be chosen based on the specific chemicals they will carry, as some substances are more challenging to manage than others. Chemical resistance charts and materials testing play significant roles in this decision-making process. By using the right corrosion resistant pipes, industries can avoid costly downtimes and regulatory penalties, ensuring both compliance and sustainability.

6. Flexible Pipes for Unique and Challenging Environments

In some situations, flexibility is key. Flexible pipes can easily navigate around obstacles and are ideal for unusual shapes and tight spaces. They are often used in environments where traditional rigid pipes would be impractical. Their ability to flex and bend makes them particularly useful in earthquake-prone areas or places with unstable ground conditions, where rigid pipes might crack or break under pressure.

Furthermore, flexible pipes can simplify installation and reduce the need for additional joints or fixtures. Materials like flexible PVC or composite layers offer both durability and the necessary pliability. These pipes are also valued in cutting-edge applications like renewable energy installations, where they enable innovative designs and efficient space utilization. When selecting flexible piping options, it’s essential to balance flexibility with strength to ensure lasting performance and reliability.

7. High Pressure Pipes for Water Supply Systems

Designed to withstand high pressure, these pipes are crucial in areas with demanding water supply requirements. They ensure a consistent and robust flow of water, reducing the risk of bursts and leaks. Materials like steel or copper are commonly used, due to their ability to maintain performance under intense pressure. These pipes play a vital role in urban utilities and critical infrastructure developments that must deliver reliable service without interruption.

High pressure pipes are not just limited to water utilities. They also find applications in gas distribution networks and other fluid transport systems where pressure stability is required. Choosing the right gauge and grade can drastically affect the system’s overall efficiency and safety. When dealing with high pressure systems, regular maintenance and inspections are key to early detection of potential issues, ensuring long-term operational integrity.

8. Low Pressure Pipes for Gravity Systems

Used in systems where gravity assists the flow, low pressure pipes are ideal for applications such as drainage and irrigation. They offer an efficient way to manage lower pressure scenarios. These systems leverage natural forces to transport water and waste, promoting sustainable and energy-efficient designs that minimize infrastructure needs.

Materials for low pressure pipes often include PVC or clay, which are both cost-effective and adept at handling moderate loads over long periods. They are specifically designed to optimize flow efficiency in downhill or flat terrains, making them a staple in green building designs and eco-friendly irrigation projects. Proper planning and installation ensure that these systems remain clog-free and require minimal maintenance, offering a reliable solution in both rural and urban settings.

9. Insulated Pipes for Temperature Sensitive Transport

Insulated pipes are essential in scenarios where temperature control is critical. They are used to transport fluids that need to maintain a consistent temperature, protecting the medium from external temperature fluctuations. This is especially crucial in applications like HVAC systems or cold chain logistics, where temperature deviations could compromise product quality or system performance.

Insulation materials such as foam rubber or mineral wool are commonly used to wrap these pipes, providing a layer of weather and heat resistance. This not only stabilizes the temperature of the transported materials but also enhances energy efficiency by minimizing heat loss or gain. For industries like brewing or pharmaceutical manufacturing, maintaining precise temperature conditions through insulated piping is key to achieving production consistency and quality assurance.

10. Double-Walled Pipes for Improved Safety

For maximum safety, particularly in transporting hazardous materials, double-walled pipes provide an extra layer of protection. They are built to contain leaks within the inner layer, providing peace of mind and enhanced security. These pipes are frequently used in industries where leak prevention is paramount, such as in chemical processing or oil and gas sectors.

By employing double-containment systems, these pipes prevent environmental contamination and safeguard workers from exposure to dangerous substances. The outer layer acts as a fail-safe, ensuring that any breach in the inner pipe does not lead to immediate external leaks. This design not only boosts environmental safety but also complies with stringent industry regulations, making double-walled pipes a favored choice for risk management in high-stakes environments.