Understanding the Essentials of Industrial Pipes in Power Generation

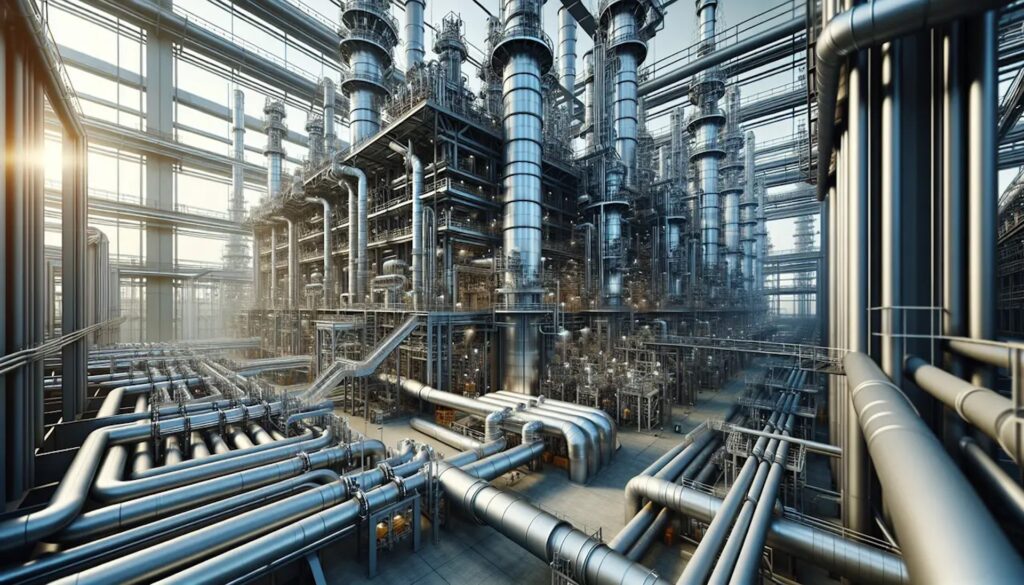

Industrial pipes are the unsung heroes of the power generation process. They form an intricate network that transports everything from cooling water to steam, facilitating the production and distribution of electricity. This system is crucial for maintaining the balance between energy generation and consumption. Without these pipes, many processes within a power plant would come to a standstill. For instance, in nuclear power plants, pipes are essential for the heat exchange systems, which play a critical role in generating steam required to power turbines.

Moreover, different types of pipes are specifically designed to handle the high temperatures and pressures typical in power generation environments. Materials such as stainless steel are often used due to their durability and resistance to corrosion, making them ideal for long-term use. The role of industrial pipes isn’t just functional, it also impacts the efficiency and safety of power plants. With the growing demand for energy, understanding the vital role these components play helps in appreciating why a trusted supplier is necessary for optimal performance.

The Role of Quality in Industrial Pipes

Quality assurance in industrial pipes begins with the selection of high-grade materials designed to withstand extreme environmental conditions. A reliable supplier will ensure their products meet industry-specific standards, such as those set by the American Society of Mechanical Engineers (ASME). These standards confirm that the pipes can endure the rigorous demands of the power generation environment, thereby minimizing the risks of leaks, which can lead to catastrophic failures. This commitment to quality plays a significant role in preventing unscheduled downtimes, which not only affect production but also can have safety implications.

Furthermore, quality pipes contribute to the overall efficiency of a power plant. They help maintain consistent pressure levels and temperatures, thereby allowing for a more stable operational workflow. Each component, meticulously designed and crafted, ensures a streamlined energy production process. For large-scale power projects, the assurance of quality from an industrial pipe supplier can be the distinguishing factor between success and failure.

The Importance of Supplier Reliability

Reliable suppliers serve as a backbone to any power generation project. Their ability to meet strict deadlines and deliver high-quality products consistently is crucial. Not only does this reliability ensure seamless operations, but it also builds trust with power generation companies. Supplier reliability extends beyond delivery schedules. A dependable supplier will also provide comprehensive support and advice, often acting as partners in the process. They can adapt to unique project needs, offering customized solutions that address specific pipelines requirements and challenges.

It’s not just about the pipes themselves—having a reliable supplier ensures that any challenges are met with prompt and effective solutions, minimizing disruptions. Additionally, they may offer valuable insights into industry trends and advancements, which can be integral for staying ahead in the fast-evolving field of power generation. The consistent support and innovation from a trustworthy supplier ultimately translate to operational precision and enhanced capacity to meet energy demands efficiently.

Safety and Compliance with Environmental Standards

In the arena of power generation, safety and environmental compliance are paramount. Industrial pipe suppliers must ensure that their products are not only effective but also safe for use under the stringent standards set by environmental and safety regulations. Adherence to such standards helps prevent environmental hazards, which can have far-reaching effects on both local ecosystems and human populations.

The integration of environmentally-friendly materials and practices by suppliers is increasingly important. This is particularly vital in sectors like power generation, where the environmental footprint of operations is scrutinized. Advanced technologies are being deployed to ensure that pipes not only meet but exceed safety standards—ensuring that leakages and failures are minimized. By prioritizing safety and compliance, a reliable supplier helps to uphold the integrity of power generation infrastructure, supporting both human safety and ecological preservation.

Cost-Effectiveness and Long-Term Investment

Investing in high-quality pipes can initially seem costly, but it ultimately serves as a long-term financial strategy for power generation companies. These pipes demand less maintenance, which translates to fewer production halts and a longer operational lifecycle. Over time, this reduces operational costs significantly, contributing to a more sustainable financial model for power plants.

Furthermore, the use of superior materials and advanced craftsmanship allows for optimized energy efficiency, reducing waste and improving the output of power generation facilities. By cutting down on frequent repairs and replacements, a long-term investment into quality industrial pipes contributes to the overall sustainability of a company’s financial health and operational capabilities.

The Value of Technological Expertise

In today’s technologically advanced world, the input and expertise a knowledgeable industrial pipe supplier can bring are invaluable. These experts not only provide high-quality products but also offer consultations that guide power generation strategies. Technological expertise enables suppliers to recommend cutting-edge solutions tailored to complex operational requirements. Such insights are critical in sectors where technology is rapidly changing, and there is constant pressure to improve efficiency and minimize environmental impact.

Furthermore, a supplier with technological expertise can assist in the integration of new technologies that enhance operational resilience. As the energy sector evolves with innovations like smart grids and IoT-enabled facilities, having a supplier who understands this landscape becomes an asset. Their capability to align products with technological changes ensures that power generation facilities remain future-ready and competitive.

Final Thoughts on Choosing Your Industrial Pipe Supplier

In the power generation industry, the importance of a reliable industrial pipe supplier cannot be overstated. From technological expertise to unwavering safety and environmental standards, choosing the right supplier is a cornerstone of operational success. By ensuring quality, reliability, and support, an esteemed supplier always contributes toward safer, more efficient, and more cost-effective power generation operations. To learn more about how we can support your needs, visit our homepage.