While the world focuses on sustainability and recycling, the truth is that barely eight percent of plastic is recycled. That’s compared to 93% of all structural steel, recycled back into new steel products, making steel one of the most recycled materials in the world.

The Recyclability of Steel

Steel is a unique material that can be recycled indefinitely without losing its properties. Steel products are durable and have long-useful life spans that can often be recycled and repurposed in other applications. As the steel industry cleans up its act, we continue to make our mark in the world by reducing the environmental impact of our steel products in every phase of its lifecycle.

Steel’s Life Cycle

Understanding the life cycle of a product is key to finding the sweet spot of sustainability. By measuring the social, environmental, and economic impact of products, we can see the entire length of steel’s life cycle and focus on its infinite reusability.

Sourcing Raw Materials

The process starts by choosing suppliers worldwide that harvest raw materials following clean initiatives and responsible practices. This process involves making sure a supplier’s sustainability policy aligns with our promise of focusing on clean, environmental practices.

Steel Production

The next step is to focus on the different processes used in the production of steel. There are two popular processes used in steel production: basic oxygen steelmaking (BOS) and electric arc furnaces (EAF). Within these, industry-wide improvements in technology help reduce CO2 emissions during the production stage.

Recycling of By-Products

For a complete reusable production process, residuals generated in the steelmaking process are recirculated in different steel production processes where it is possible to substitute raw materials. Resulting in decreased waste volumes and increased material efficiency by allocating by-products in other processes within steel’s lifecycle.

Product Manufacture

During the manufacturing process, it’s important to recognize different ways the use of high-strength steel can improve the reusability of materials. Most of the pre-consumer steel scrap will be sent back to the production step for reuse and recycling.

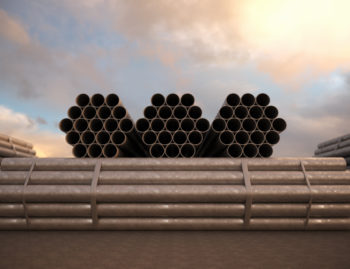

Post-Consumer Scrap

After using steel for its various applications, post-consumer scraps can be used for reuse and remanufacturing. Thanks to the ability of steel to lose virtually none of its properties during the manufacturing process. Post-consumer steel scraps are 100% recyclable and can continue moving through the lifecycle of steel for perpetuity.

After Product Use of Steel

At last, steel re-enters the lifecycle as post-consumer scraps. At this point, steel has served its first life, and it’s ready to start the process all over again. However, there’s currently not enough steel scrap to meet the steel demand, so the need to produce steel from iron in the future is still very prominent.

Still, all the steel scrap continues to be pushed down the lifecycle to become reused, repurposed, and recycled once again, and the low energy use and the focus on conservation of natural resources to produce steel which is why steel remains the leading choice for sustainable materials.