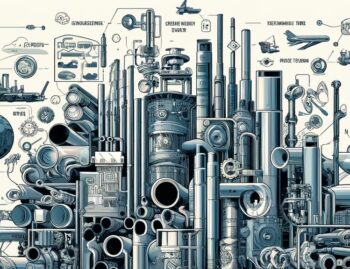

That could not be farther from the truth. In fact, there are over 3,500 different types and grades of steel. These different types can be put into four broad groups.

All steel is an alloy of carbon and iron, and different types can be created depending on how much carbon is used. Each type has different properties and uses.

Carbon Steel

Carbon steels are the most common types of steel, making up more than 90% of all steel produced worldwide.

Steel is considered carbon steel when its carbon content is between .12% and 2.0%, and it doesn’t contain a significant amount of any other alloying material.

Depending on the carbon content, carbon steel can be broken into three smaller groups: low carbon steels (up to .3% carbon), medium carbon steels (.3-.6%), and high carbon steels (more than .6%).

The most common type of carbon steel is low carbon, aka mild steel, aka plain-carbon steel. It’s cheaper than its higher-carbon counterparts, but is still extremely useful.

Alloy Steels

Alloyed steel, as the name implies, is steel that has been alloyed with another element in order to change its properties.

While all steel is, by definition, an alloy (it’s a combination of carbon and iron), not all steel is considered “alloyed steel.” How much of an element must be present for the steel to be called alloyed steel depends on the element.

Some elements that are used to make alloy steels: aluminum, nickel, copper, silicon, tungsten, chromium, and molybdenum ( chromium and molybdenum alloy is informally referred to as chrome moly).

Which element you use depends on which property of the steel you’d like to change. For example, adding nickel (or various other elements) increases the steel’s corrosion resistance, while adding tungsten will increase the melting point.

This makes alloy steel useful for a wide variety of things, and also allows it to be subjected to various heat treating methods to increase its strength and hardness.

Stainless Steel

This is the one that most people have heard of, and tend to think of as “steel.”

Stainless steel is usually alloyed with chromium, which increases the corrosion resistance by up to 200 times that of low carbon steel.

It can be broken down into three groups:

Austenitic – This is the most common type of stainless steel. It contains highest amount of chromium and nickel, and is the type usually used for kitchen equipment like counters or cooking tools.

Ferritic –Contains a tiny bit of nickel and carbon, and less than 18% chromium, along with other alloy metals. It has magnetic properties, cannot be hardened with heat, but can be strengthened with cold treatment.

Martensitic – This stainless steel has about the same amount of carbon as the others, but a little bit more nickel and a lot more carbon. It is heat-treatable, and usually used for knives and medical equipment.

Tool Steels

As the name implies, these are steels that are made with the express purpose of making tools.

They’re generally made with materials like tungsten, cobalt, or any others that can increase heat resistance and durability, which makes them a great option for cutting and drilling equipment.

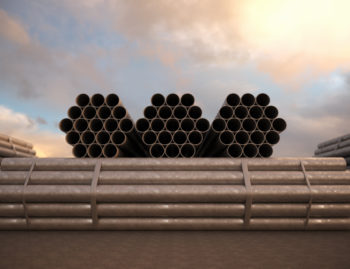

Most of these types of steels can be used to make steel pipes, so it’s important that you know what type best suits your needs. Remember to call your friends at Federal Steel Supply to help you make the right decision!