While some exotic implementations required unusual materials, common metals and plastics would suffice for almost any ordinary task. What people have discovered over time is that steel usually offers the best traits in which to get the job done in a safe and efficient manner.

Greater Accidental Impact Resistance

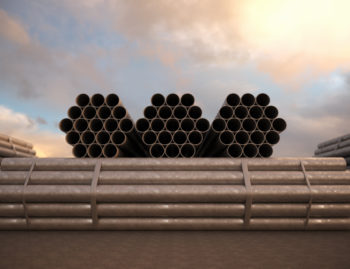

Two main families of material have come to dominate common applications in piping. Plastic and steel both have their pros and cons that must be considered.

One of the greatest benefits to using steel is the added strength to withstand accidental impact. In high traffic areas or locales were workers are present, steel is king to avoid issues of liability. Forklifts, robotics, and other autonomous agents of industry can all fall prey to industrial accidents.

When impacts under the catastrophic level occur, steel greatly increase the chance of absorbing the blow and keeping the system up and running.

Applicable to a Great Many Uses

A great many uses have been derived from using steel pipe. It has the strength to be used as a structural component such as columns, handrails, and poles. Ease of construction has lent it to being the staple of the scaffolding industry.

Forged to high standards of strength, society chooses to use it to transport our sewage safely away from us and our environment. Increased protection for personnel is afforded when using steel to house electrical conductors.

The applications are virtually limitless for this tried and true material when used in pipe construction.

Carbon Steel is the King of the New Economy

Additional restrictions in this stringent economy have resulted in industry looking for the next generation of material that offers most of the benefits of steel but at a reduced cost. With this in mind, carbon steel was developed as a viable alternative. It filled the breech for a great many tasks in which a more expensive form of steel was previously used.

Metallurgists have discovered that by adding the proper proportion of carbon to their steel that the strength greatly increases. This is necessary for the times in which you have water systems that go through numerous pressure fluctuations. It has the ability to absorb those internal hammer blows without rupturing.

Environmentalists and the green movement like this because of the significant percentage of material that can be recycled when the system needs to be taken back down.

Finally, it lasts much longer which means that long term replacement costs are defrayed for much longer.

The case for steel is clearly evident. Armed with this information, it is easy to convince anyone in control of the budget that steel is the way to go. Piping remains vital in our lives and steel will be there to make sure the job is done safely.